Introduction:

In the dynamic landscape of heavy equipment construction, the seamless movement of machinery is a critical orchestration that sets the tone for project efficiency. Pile driver, the formidable giants responsible for shaping foundations, demand careful planning and execution when it comes to their transportation and mobilization on construction sites. This article delves into the intricate logistics of moving these hefty machines, exploring the methods, equipment, and strategies that ensure their integration into heavy equipment operations with precision and efficacy.

The Prelude: Preparation for Transport

Understanding Dimensions and Weight Before the journey begins, a comprehensive understanding of the pile driver dimensions and weight is imperative. These measurements dictate the type of transportation required and influence the choice of routes that can accommodate the machine’s size and weight.

Choosing the Right Transport Mode Transporting pile driver involves a variety of modes, ranging from flatbed trucks to specialized trailers. The mode chosen depends on factors such as the distance to the construction site, the local road infrastructure, and any legal regulations that govern oversized loads.

Securing for the Journey: Load Restraints and Safety Measures Ensuring the pile driver stability and safety during transportation is paramount. Load restraints, such as chains and straps, are used to secure the machine to the transport vehicle. Additionally, safety measures, including proper signage and lighting, help alert other motorists to the presence of an oversized load on the road.

The Dance of Mobilization

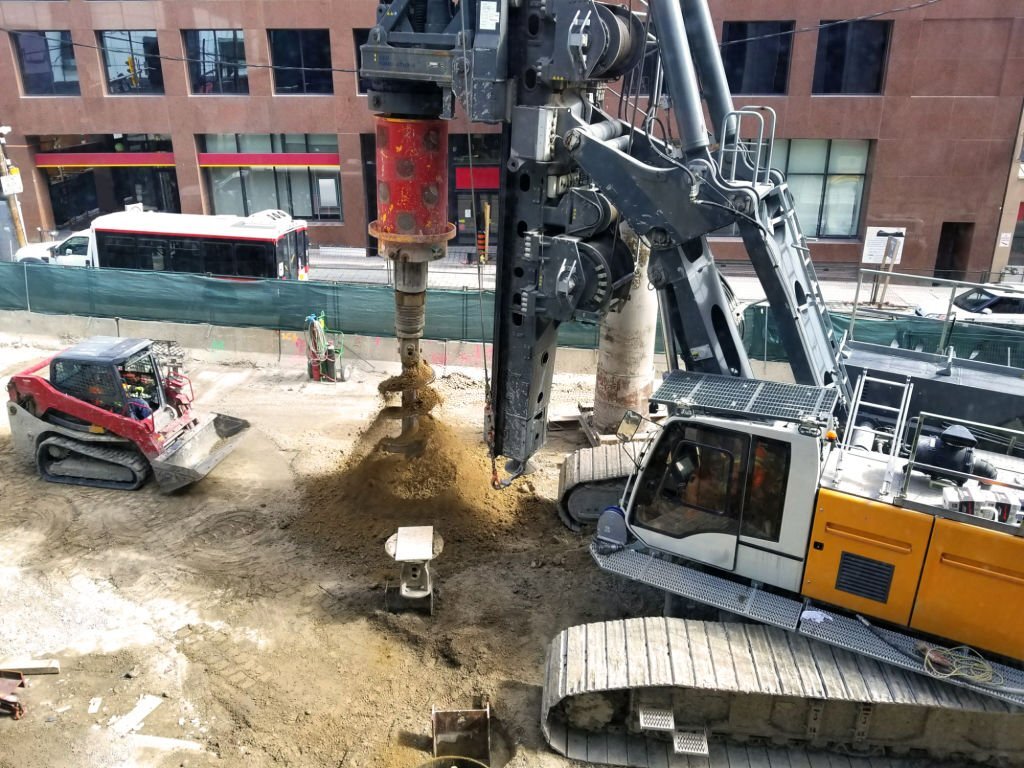

Site Assessment and Preparation Arrival at the construction site marks the beginning of the mobilization process. Site assessment is crucial to determine the optimal location for the pile driver setup. Factors such as ground stability, proximity to the work area, and access to other construction equipment are considered.

Crane Lifting and Assembly Pile driver often arrive at the construction site disassembled to facilitate transportation. Once on-site, cranes are employed to lift and carefully assemble the machine. This process demands precision and coordination to ensure that all components are aligned correctly.

Fine-Tuning for Optimal Performance: Calibration of Pile Driver

As the final step in the mobilization process, calibration emerges as a crucial endeavor that unlocks the full potential of pile driving on construction sites. While assembly transforms disassembled parts into a unified whole, calibration fine-tunes each component to orchestrate the perfect harmony between the machine’s capabilities and the demands of the project. This meticulous calibration ensures that the pile driver are not only delivered with precision but also maximize efficiency, creating a symphony of power and accuracy that reverberates through the construction site.

, an artistry of construction, anchor structure to the Earth’s embrace. The rhythmic thud of the hammer meeting steel reverberates as foundations take shape. From towering skyscrapers to sturdy bridges, this process ensures stability and resilience. Piles, be they steel, concrete, or timber, penetrate the ground, becoming steadfast sentinels that withstand the test of time. The act of driving piles transcends mechanics; it’s a testament to human mastery over the forces of nature. With each pile driver, a connection is forged between innovation and the Earth, solidifying the structure that shape our world and providing a tangible link between human ambition and the ground beneath our feet.

The Art of Matching Soil Conditions

One of the key aspects of pile driver calibration is adapting the machine to the unique soil conditions of the construction site. Soil types can vary significantly, from loose sand to compact clay, each demanding a specific approach to ensure optimal pile driving. Hydraulic systems, the backbone of the machine’s force delivery, are adjusted to accommodate the specific resistance and compaction characteristics of the soil. This calibration prevents overdriving or underdriving of piles, ensuring that the impact force is optimized for maximum penetration.

Tailoring to Project Requirements

Every construction project comes with its own set of specifications and requirements. Calibration ensures that the pile driver impact energy, frequency, and stroke length are aligned with these demands. For instance, a high-rise building might require deeper pile penetration, necessitating adjustments in the pile driver settings. Similarly, a project in a noise-sensitive area might call for lower impact frequencies. Calibration tailors the machine to the project’s unique nuances, enhancing its effectiveness and minimizing unnecessary energy consumption.

Holistic Calibration: From Hydraulics to Controls

Calibration extends beyond the hydraulic systems to encompass the entire operational spectrum of the pile driver. Hammer mechanisms, responsible for generating the impact force, are calibrated to strike with the optimal amount of energy. Control panels, equipped with advanced technology, are fine-tuned to provide operators with intuitive and precise control over the machine’s functions. This holistic approach ensures that every facet of the pile driver operation is synchronized for optimal performance.

Pile Driver: Forging Foundations of Strength and Stability

In the bustling realm of construction, where every structure aspires to touch the sky or span great expanses, the pile driver emerges as a silent yet formidable force. A marvel of engineering, this essential equipment is entrusted with the monumental task of creating foundations that withstand the test of time.

At its heart, a pile driver is a symphony of power and precision. Its purpose is simple yet profound: to drive piles deep into the ground. These piles, often constructed from materials like steel, concrete, or timber, form the bedrock upon which colossal structure rest. The pile driver’s symphony begins with calculated force, delivering repeated blows to the pile, urging it to gradually embed itself into the earth.

From towering skyscrapers that touch the clouds to bridges that span mighty rivers, the pile driver leaves its indelible mark on the world’s architectural marvels. It is the unsung hero that shapes the landscapes of progress, silently ensuring stability and longevity.

Yet, the pile driver is more than a mechanical behemoth; it symbolizes the fusion of human ingenuity with the raw power of nature. Its rhythmic cadence reflects the tireless dedication of engineers and construction teams who orchestrate this dance of mechanics, turning dreams into reality.

The pile driver, a formidable presence in the world of construction, emerges as a pivotal force in laying the groundwork for monumental structure. This engineering marvel holds the responsibility of driving piles – sturdy columns often composed of materials like steel, concrete, or wood – deep into the ground, forming the essential foundation upon which towering skyscrapers, resilient bridges, and steadfast structure are built. With meticulous precision, the pile driver delivers controlled and rhythmic blows, each impact urging the pile further into the earth’s embrace.

The symphony of power and accuracy performed by the pile driver is a testament to human ingenuity harnessed for the greater good. Its rhythmic cadence resonates as a silent ode to the dedication of engineers and construction teams working to ensure stability and longevity in architectural endeavors. The piles, once fully embedded, provide essential support, anchoring structure against the forces of nature and the test of time.

As the pile driver goes about its task, it embodies the marriage of mechanics and ambition. Its impact is felt not only in the physical act of driving pile but also in the enduring legacies it helps create. The pile driver, standing tall amidst sites, symbolizes the unwavering commitment to building foundations of strength that mirror the aspirations of a progressive world.

The pile head, a crucial juncture in constructions, marks the interface where structural strength converges. It’s where the support of foundations meets the aspirations of towering structure, embodying the essential connection that enables architectural marvels to rise with stability and purpose.

Vibratory Pile Drivers: Powering Foundations for Diverse Structures

In the intricate landscape of constructions, where solid foundations serve as the bedrock of architectural marvels, vibratory pile drivers stand as stalwarts of strength and precision. These specialized machines play a pivotal role in driving various types of pile, such as concrete pile drives, wood pile, and pipe pile, into the earth’s embrace, enabling structure to rise with stability and resilience.

Diverse Pile Types and Applications:

Vibratory pile drivers exhibit remarkable versatility, accommodating a spectrum of pile materials and constructions contexts. Concrete pile, known for their load-bearing capacity, find a secure home beneath the rhythmic embrace of vibratory pile drivers. Wood pile, favored for their eco-friendly attributes and ease of installation, are driven deep into the ground with a gentle yet firm touch. Pipe, integral to foundation support in marine environments, are effortlessly installed by these machines, making underwater constructions a reality.

Mechanics Behind the Magic:

At the heart of the vibratory pile lies a sophisticated mechanism that orchestrates their efficacy. These machines utilize counter-rotating eccentric weights to generate vibrations that transmit through the pile, reducing friction between the pile and surrounding soil. This friction reduction facilitates smoother penetration, enabling pile to be driven to desired depths with less effort. Additionally, the application of vibratory forces minimizes ground disturbance, a critical factor in projects where environmental impact is a concern.

Advantages and Efficiency:

Vibratory pile present a suite of advantages that make them indispensable in modern constructions. Their precision-driven approach minimizes noises pollution, a boon in urban settings where noise regulations are stringent. The lack of excessive noise not only contributes to a harmonious work environment but also minimizes disturbances for nearby residents. Moreover, the efficiency of the vibratory pile significantly reduces the time required for pile installation, expediting constructions timelines and ultimately reducing project costs.

Challenges and Innovations:

While vibratory pile are incredibly efficient, certain challenges necessitate ongoing innovation. For instance, underwater constructions requires adaptations to account for water resistance and other aquatic factors. However, advancements in technology and engineering have paved the way for vibratory pile that excel in underwater environments, ensuring the stability of structures built beneath the waves.

Evolution of Pile Driving:

Vibratory pile stand as a testament to the evolution of pile-driving techniques. In contrast to traditional methods like steam hammer drives that relied on impact to drive pile, vibratory pile offer a gentler yet equally effective approach. The ability to transmit vibrations to pils has transformed the landscape of constructions, enabling the installation of pile with minimal environmental impact and maximal efficiency.

In conclusion, vibratory pile have emerged as transformative tools in the realm of constructions. From concrete pile to wood piling and underwater piling installations, their versatility and precision have reshaped the foundation of modern architectural feats. As technology continues to advance, these machines will likely play an even greater role in ensuring the stability, sustainability, and efficiency of constructions projects across the globe.

Deep Foundations and Vibratory Hammers: A Dive into Pile Driving Techniques

In the early stages of constructing large structures like bridges, docks, and commercial complexes, the foundation sets the stage for stability and longevity. One of the most effective methods of creating deep foundations is pile driving, a technique that involves embedding pile into the grounds to support the weight of the structure. Pile can be made of various materials, including concrete, steel, and wood, tailored to suit specific project requirements.

Traditionally, pile driving involved techniques like using impact blocks dropped from a height, creating vertical vibrations to drive the driver into the grounds. However, advancements in constructions equipment have introduced vibratory hammer that utilize horizontal vibrations to achieve the same result more efficiently.

The Power of Vibratory Hammer:

Vibratory hammer have revolutionized the piling process, employing a piston that compresses air to create rapid horizontal vibration. This motion transmits energy , allowing it to penetrate the grounds with minimal impact on the surrounding environment. Unlike traditional impact methods that generate significant noises and disturb the soil, vibratory hammer emit less noises and offer greater control over the piling process.

Diverse Applications and Techniques:

Commercial divers play a crucial role in the implementation of deep foundation techniques in underwater constructions required. In scenarios where need to be driven into waterbeds, compressed air is used to create a dry working environment beneath the water’s surface. Commercial divers, equipped with specialized equipment, work in harmony with vibratories hammers to install underwater.

The types used and the specific techniques employed depend on the project’s requirements. For instance, are ideal for areas with challenging soil conditions, while concrete piles provide robust support for heavy structures. Wood piling offers an eco-friendly option for projects that prioritize sustainability.

Balancing Efficiency and Environmental Impact:

Vibratory hammer strike a delicate balance between efficiency and environmental responsibility. The reduction of noises pollution during the piling process benefits nearby communities, and the minimized ground disturbance helps maintain the ecological balance of the area.

Conclusion: Harmony in Movement

The seamless transportation and mobilization of pile drivers epitomize the harmonious blend of engineering prowess and logistical finesse. From understanding dimensions to selecting transport modes, from careful assembly to precise calibration, each step is orchestrated to ensure that these heavy machines seamlessly integrate into the symphony of heavy equipment construction. As the industry advances, the choreography of moving and mobilizing pile drivers evolves, reflecting the determination to maximize efficiency, minimize downtime, and craft a construction landscape that is as precise in movement as it is in execution.

#heavy weight #hydraulic hammer #diesel hammer #build docks #piston compresses #impact block #wood piles#pile drivers #underwater construction required #other types #head#large variety #pipe piles #kick#the kick#person #the person #point #machine #the machine #hit #the hit