Introduction

Sweeper machines play a crucial role in maintaining cleanliness and safety on construction sites, warehouses, industrial facilities, and roadways. These heavy equipment attachments are responsible for sweeping debris, dust, and dirt, making them indispensable in various industries. To ensure these machines perform efficiently and safely, proper maintenance is essential. In this article, we will delve into the maintenance requirements for sweeper machines in heavy equipment, highlighting key tasks and best practices.

Regular Cleaning

One of the fundamental maintenance tasks for sweeper machines is regular cleaning. Sweeper brushes and mechanisms can accumulate dirt, debris, and other materials during operation, which can affect their performance over time. Here are some cleaning tips:

- Daily Cleaning: After each use, remove debris and dirt from the sweeper brushes, hopper, and filters. Use compressed air or a broom to clean hard-to-reach areas.

- Weekly Inspection: Perform a more thorough weekly inspection, checking for loose or damaged parts. Ensure the brushes are clean and free from obstructions.

Inspect and Replace Bristles

The bristles or brushes on sweeper machines wear out over time due to continuous contact with the ground. Regularly inspect the condition of the bristles and replace them when they become worn or damaged. Maintaining proper bristle length and shape is crucial for effective sweeping.

Lubrication

Heavy equipment, including sweeper machines, relies on various moving parts and components. Proper lubrication is vital to reduce friction, prevent wear and tear, and ensure smooth operation. Refer to the manufacturer’s guidelines for specific lubrication points and schedules.

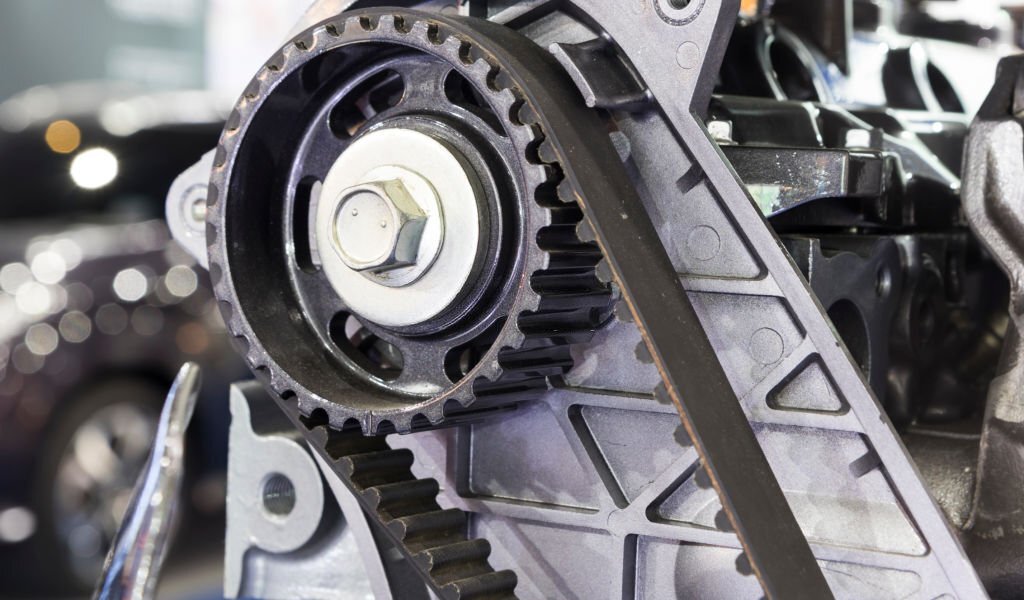

Belt and Chain Maintenance

Sweeper machines often use belts or chains to drive the brushes and other components. Inspect these belts or chains regularly for signs of wear, tension, or damage. Loose or damaged belts and chains can lead to reduced efficiency and costly breakdowns.

Hydraulic System Check

If your sweeper machine is equipped with a hydraulic system, regularly inspect it for leaks, damaged hoses, or low fluid levels. Hydraulic issues can affect the machine’s ability to operate efficiently and may result in safety hazards.

Filter Replacement

Sweeper machines rely on filters to prevent dust and debris from entering critical components. Ensure you replace air and hydraulic filters as recommended by the manufacturer to maintain the machine’s performance and prevent engine damage.

Electrical System Inspection

For sweeper machines with electrical components, check all wiring, connectors, and switches for wear, damage, or loose connections. Faulty electrical systems can cause unexpected malfunctions and pose safety risks.

Safety Checks

Safety is paramount when maintaining sweeper machines. Regularly inspect safety features, such as emergency shut-off switches, warning lights, and backup alarms. Ensure that all safety systems are in good working order to protect operators and bystanders.

Operator Training

Lastly, proper operator training is a critical aspect of sweeper machine maintenance. Ensure that operators are trained in safe and efficient machine operation, as well as basic troubleshooting procedures. Knowledgeable operators are more likely to identify and address maintenance issues promptly.

Conclusion

Maintaining sweeper machines in heavy equipment is essential to ensure their longevity, performance, and safety. Regular cleaning, inspection, and servicing are vital aspects of this maintenance process. By following these maintenance requirements and best practices, you can maximize the efficiency and reliability of your sweeper machines, ultimately leading to a safer and more productive work environment.