In our relentless pursuit of modernization and development, crushing and screening equipment have become indispensable tools in the construction, mining, and recycling industries. These powerful machines play a pivotal role in processing raw materials, shaping our urban landscapes, and advancing infrastructure. However, this technological advancement comes at a price, with significant environmental consequences that are often overlooked.

This article delves into the environmental impacts of crushing and screening equipment, shedding light on the challenges and responsibilities associated with their use. From energy consumption and air pollution to habitat disruption and water usage, we explore the various ways in which these processes affect our planet. By understanding the environmental repercussions of these essential operations, we can strive to strike a balance between our development needs and the preservation of the environment, paving the way for more sustainable and responsible practices in these critical industries.

1. Energy Consumption

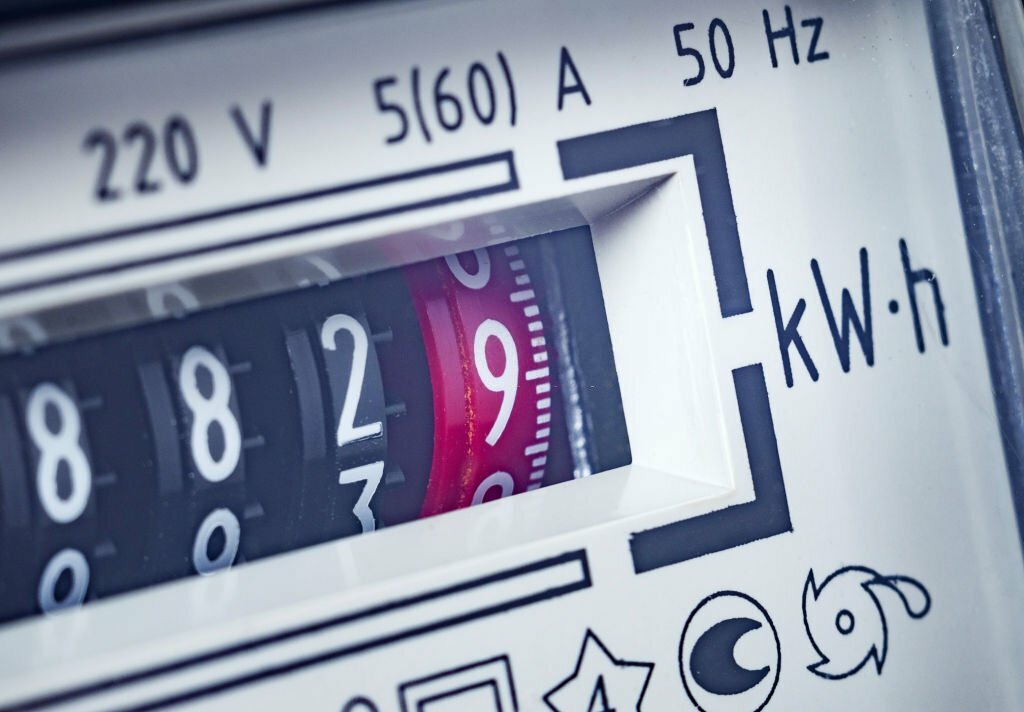

One significant environmental impact of crushing and screening equipment is their substantial energy consumption. These machines are powerhouses designed to crush, separate, and transport heavy materials, demanding copious amounts of electricity or fuel to function effectively. In fact, the mining and construction sectors, which rely heavily on such equipment, are among the largest contributors to global energy consumption. This, in turn, plays a significant role in the emission of greenhouse gases and ultimately exacerbates the global challenge of climate change.

To address this pressing concern, manufacturers in the industry are responding with a concerted effort to develop more energy-efficient equipment. These innovative designs aim to reduce the carbon footprint associated with crushing and screening operations. By employing advanced technologies, such as more efficient motors, improved power management systems, and the integration of renewable energy sources, these machines can optimize their energy use and minimize their impact on the environment. This shift towards energy efficiency not only benefits the environment but also offers long-term economic advantages by lowering operational costs and reducing the industry’s reliance on non-renewable energy sources. In doing so, the crushing and screening industry takes a positive step towards a more sustainable and environmentally responsible future.

2. Air Pollution

Crushing and screening equipment are indispensable in industries like mining and construction, but they bring a notable environmental challenge in the form of air pollution. These machines can release various pollutants into the atmosphere, including particulate matter, volatile organic compounds, and nitrogen oxides, which can have adverse effects on both human health and the environment.

Dust and emissions from diesel engines are among the primary sources of air pollution at mining and construction sites. To address this issue, the implementation of proper dust control measures is crucial. Water sprays and advanced filtration systems are effective tools for mitigating these emissions. Water sprays suppress dust by binding particles together, preventing them from becoming airborne. Advanced filtration systems, on the other hand, capture and remove pollutants from exhaust gases before they are released into the atmosphere, reducing the emission of harmful compounds.

By adopting these dust control measures, the crushing and screening industry can significantly minimize its impact on air quality, protect the health of workers, and contribute to a cleaner and more sustainable environment.

3. Noise Pollution

The operation of crushing and screening equipment is often characterized by the generation of substantial noise levels, which can have far-reaching consequences for both the environment and human well-being. High noise emissions associated with these activities can disrupt local ecosystems by disturbing wildlife habitats and altering the behavior of animal species, potentially leading to ecological imbalances.

Furthermore, the impact extends to nearby communities, where noise pollution can cause annoyance, stress, sleep disturbances, and even long-term health issues in residents. Prolonged exposure to high noise levels has been linked to cardiovascular problems, hearing impairment, and psychological stress.

To address these challenges, the industry is actively investing in noise-reducing technologies and enhanced equipment designs. These innovations aim to minimize noise emissions, creating a quieter operational environment. By embracing these advancements, the crushing and screening sector seeks to strike a harmonious balance between its vital functions and the preservation of both natural ecosystems and the well-being of neighboring communities. This proactive approach underscores the industry’s commitment to responsible and sustainable practices.

4. Habitat Disruption

Mining and construction activities involving crushing and screening equipment frequently lead to the disturbance of natural habitats, causing adverse effects like deforestation and biodiversity loss. These operations can result in the removal of vegetation, alteration of landscapes, and displacement of wildlife, triggering a cascade of ecological consequences.

Mitigating these impacts is crucial for preserving our planet’s delicate balance. Responsible land reclamation and habitat restoration practices are key strategies in this endeavor. Reclamation involves the process of returning the disturbed land to a state as close to its original condition as possible. It includes re-vegetation, soil stabilization, and the reintroduction of native flora and fauna. This helps in reducing soil erosion, promoting the return of wildlife, and ensuring the long-term health of the ecosystem.

Habitat restoration, on the other hand, is a broader concept that focuses on improving the overall health and functionality of ecosystems. This may involve creating new habitats, enhancing existing ones, or reintroducing native species that were affected by construction or mining activities.

By adopting these responsible practices, the mining and construction industries can play a pivotal role in minimizing their ecological footprint and conserving our natural world. These efforts not only protect valuable ecosystems but also contribute to the preservation of the Earth’s rich biodiversity, a critical component of a sustainable and harmonious coexistence with our environment.

5. Water Usage

Water plays a vital role in the operation of crushing and screening equipment, serving as a crucial resource in various processing stages. However, excessive water consumption during these processes can pose significant environmental challenges. Not only does it strain local water supplies, but it can also lead to contamination if not managed appropriately.

To mitigate these concerns, the implementation of efficient water recycling systems is a fundamental step. By recycling and reusing water, these systems significantly reduce the demand for freshwater, alleviating the pressure on local water sources. Moreover, recycling systems help minimize the environmental impacts associated with the extraction and transportation of large quantities of water.

Efficient water recycling not only benefits the environment but also enhances the sustainability and cost-effectiveness of crushing and screening operations. By carefully managing this precious resource, the industry can reduce its ecological footprint and contribute to the responsible and sustainable use of water, a resource vital for ecosystems and human communities alike.

Understanding the environmental impacts of crushing and screening equipment is a critical step toward ensuring responsible and sustainable industrial practices. These machines are integral to various industries, but they come with significant ecological consequences, from energy consumption and air pollution to habitat disruption, water usage, and noise pollution. To address these challenges, manufacturers and operators are investing in innovative solutions to reduce environmental footprints. By embracing energy efficiency, emission reduction technologies, and responsible land reclamation, we can strike a balance between development and environmental preservation. The path to a more sustainable future involves recognizing and mitigating these impacts and safeguarding our planet for future generations.

For an in-depth exploration of the Environmental Impacts of Crushing and Screening Equipment, visit the Boom and Bucket website. Discover how these vital industries are addressing challenges related to energy consumption, air and noise pollution, habitat disruption, and more. Gain insights into innovative solutions and responsible practices shaping the future of these essential operations. Visit our website to stay informed and contribute to a more sustainable approach in these industries.