Construction equipment, often referred to as heavy machinery or plant equipment, encompasses a wide range of specialized tools and vehicles used in construction projects. From excavators and bulldozers to cranes and concrete mixers, these machines are the backbone of the construction industry. The significance of construction equipment cannot be overstated, as it plays a pivotal role in executing projects efficiently and effectively.

A Definition of Construction Equipment

Construction equipment refers to any machinery, appliance, or tool specifically designed for use in construction activities. These machines are engineered to perform tasks that would otherwise be time-consuming, physically demanding, or even impossible for humans alone.

They are built with robust materials and powerful engines to withstand heavy workloads and challenging environments typically encountered on construction sites. The array of construction equipment is vast, ranging from small hand-held tools like hammers and drills to massive earth-moving machines like excavators and loaders.

Additionally, there are specialized vehicles such as concrete pumps and asphalt pavers that cater to specific tasks within the construction domain. Each piece of equipment serves a unique purpose but collectively contributes to the seamless progression of a project.

The Importance of Construction Equipment in Various Projects

Construction equipment is an indispensable asset for any project, regardless of its scale or complexity. It enables contractors and workers to accomplish tasks more efficiently by reducing manual labor requirements while enhancing productivity.

With their immense power and capabilities, these machines expedite project timelines while maintaining quality standards. Moreover, utilizing appropriate construction equipment enhances worker safety by minimizing the physical strain associated with manual labor-intensive tasks.

The mechanized nature of these tools reduces the risk of work-related injuries caused by repetitive motions or lifting heavy loads manually. In addition to increased efficiency and improved safety measures, using suitable construction equipment ensures higher precision in project execution.

These machines offer better control, accuracy, and consistency, resulting in precise grading, leveling, and concrete pouring. Ultimately, this leads to more aesthetically pleasing structures with improved functionality.

Overall, construction equipment is not merely a set of tools; it represents the foundation upon which successful construction projects are built. By harnessing the power of specialized machinery and equipment modifications, contractors can optimize project outcomes in terms of efficiency, safety, and quality.

Overview of Construction Equipment Modification

Explanation of modification and customization

Construction equipment modification refers to the process of altering or adapting machinery, tools, attachments, or components to better suit specific project requirements. Customization entails tailoring these modifications to match the unique needs and challenges posed by a particular construction task.

Such modifications can range from small alterations, like adding attachments or improving safety features, to more extensive changes involving structural reinforcement or powertrain upgrades. Modifying construction equipment involves a combination of technical expertise and ingenuity.

Skilled professionals with a deep understanding of engineering principles and mechanical systems carefully analyze the equipment’s original design and identify areas that can be enhanced or adjusted. By leveraging their knowledge and experience, they make strategic modifications that optimize the machine’s performance while ensuring its reliability and safety.

Benefits of modifying construction equipment for specific projects

The decision to modify construction equipment for specific projects offers several significant benefits. Firstly, it enhances productivity by enabling the machinery to perform tasks more efficiently.

When equipment is tailored to meet project-specific requirements, it can handle tasks with greater precision, speed, and effectiveness. This improved efficiency not only saves time but also reduces costs associated with labor and other resources.

Secondly, customization increases versatility as modified machinery can adapt to different job site conditions or specialized tasks. Construction projects often involve various terrains, environmental factors, or unique challenges that may require specific adaptations in equipment functionality.

By customizing construction machines accordingly, contractors gain flexibility in deploying their fleet across diverse projects without compromising performance. Moreover, modified construction equipment enhances worker safety by incorporating necessary features and controls designed explicitly for the risks present in certain projects.

For instance, when working on hazardous sites such as mining operations or demolition sites with potential falling debris, reinforced structures, and additional safety measures improve operator protection. Modifying construction equipment allows for fine-tuning its capabilities according to the requirements of specific projects.

This results in increased productivity, enhanced versatility, and improved safety measures. Through strategic modifications and customization, construction professionals can optimize their equipment investment and achieve better project outcomes.

Attachment Modifications: Customizing Construction Equipment for Specific Tasks

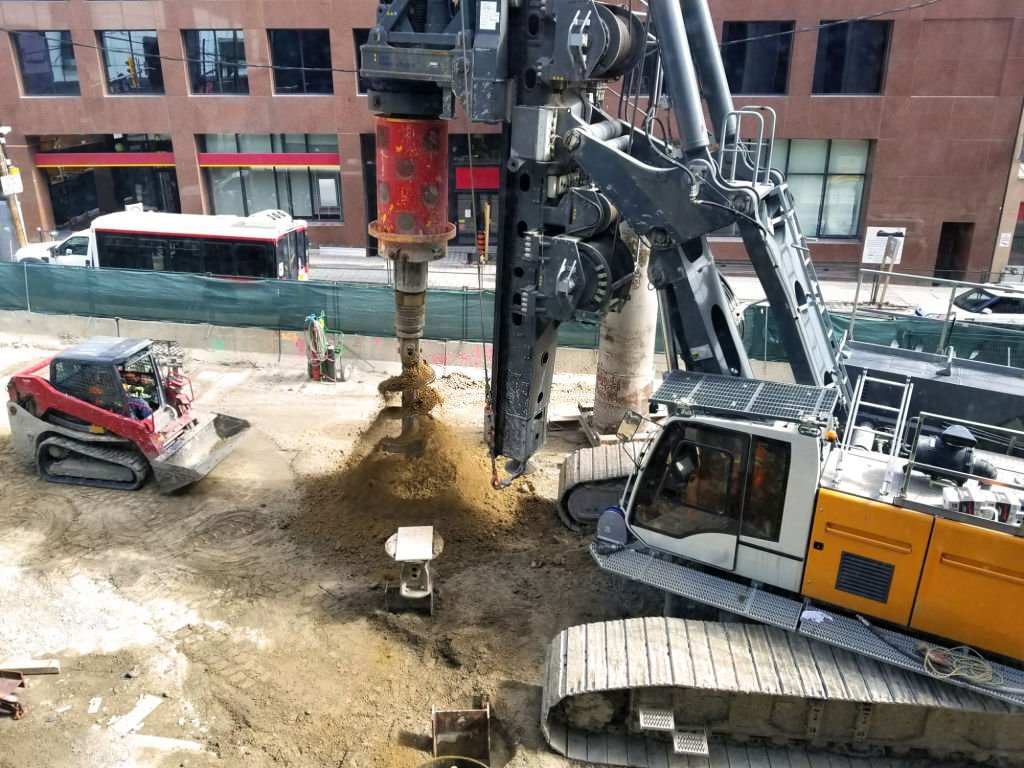

When it comes to modifying construction equipment for specific projects, attachment modifications play a crucial role. Attachments such as buckets, hammers, rippers, and augers can be customized to enhance the functionality of machinery and optimize its performance. For example, a bucket can be modified with teeth or added side cutters to improve digging capabilities or increase the bucket’s capacity.

Similarly, hammers can be customized with different tips or weights depending on the type of material that needs to be broken down. The customization of attachments extends beyond their physical features.

It also involves adapting them to suit specific tasks at hand. For instance, an excavator bucket used in a mining project may require additional reinforcement to withstand the abrasive nature of the materials being extracted.

On the other hand, a bucket used in landscaping projects may benefit from modifications that allow it to collect debris or level surfaces more efficiently. Furthermore, attachment modifications often involve incorporating advanced technologies into traditional equipment.

Augers used in drilling applications can be fitted with sensors and monitoring systems that provide real-time data on soil conditions and drilling progress. This allows operators to adjust drilling parameters accordingly and ensure maximum efficiency while minimizing potential risks.

Structural Modifications: Strengthening Construction Equipment for Heavy-Duty Projects

Construction equipment is sometimes subject to demanding tasks that require additional strength and stability beyond their standard design specifications. Structural modifications address these requirements by reinforcing the chassis or frame of machinery so that it can withstand heavy-duty use without compromising safety or performance. In heavy construction projects such as building high-rise structures or working in rugged terrains, construction equipment must endure substantial loads and impacts from materials being moved or lifted.

Strengthening the chassis ensures that machines remain stable under such stresses while maintaining functionality throughout the project duration. Additionally, altering the dimensions of construction equipment is another form of structural modification.

This allows machinery to navigate through narrow spaces or tight corners that are otherwise inaccessible. By modifying the width or height of certain components, contractors can ensure their equipment can operate effectively in constrained environments, enabling them to execute tasks precisely and efficiently.

Powertrain Modifications: Enhancing Performance and Efficiency

To maximize performance and increase efficiency, powertrain modifications are often employed in construction equipment. The powertrain refers to the system responsible for generating and transmitting power from the engine to the wheels or tracks.

Enhancing engine power and torque is a common aspect of powertrain modifications. This can involve upgrading engine components to achieve higher horsepower or modifying fuel injection systems for improved fuel combustion efficiency.

By increasing power output, machines can tackle more demanding tasks with ease while maintaining optimal operation. In addition to engine enhancements, upgrading transmission systems is another aspect of powertrain modification that deserves attention.

Advanced transmission systems offer better control over speed and torque distribution, allowing operators to match machine performance to project requirements accurately. Upgrades in transmission also enable smoother gear shifts and reduce energy losses during operation, resulting in enhanced overall efficiency for the equipment.

Specialized Modifications for Specific Projects/Industries

Construction Equipment Modifications for Mining Projects

Subtitle: Building Resilience in Challenging Environments Mining projects demand equipment that can withstand the harshest conditions, including dust, extreme temperatures, and rugged terrains. To ensure durability and longevity in such environments, construction equipment undergoes specific modifications.

One crucial modification is the integration of dust-resistant seals and filters to protect sensitive components from abrasive particles. Additionally, advanced cooling systems are implemented to tackle elevated temperatures commonly encountered in mining sites.

Safety is paramount in mining operations, which often involve hazardous tasks and challenging working conditions. Therefore, specialized modifications are made to construction equipment to enhance operator safety.

For instance, cabins are reinforced with impact-resistant materials and equipped with improved visibility features such as cameras and enhanced lighting systems. Rollover protection structures (ROPS) and falling object protection structures (FOPS) are also integrated into the design of the equipment to safeguard operators from potential accidents.

Construction Equipment Modifications for Road Construction

Subtitle: Precision Engineering for Smooth Roads Efficient road construction necessitates precise leveling and smoothness along the entire stretch. Graders and pavers play a vital role in achieving these objectives through specialized modifications tailored to this specific industry.

These modifications include using advanced laser or GPS technology that ensures accurate alignment of the equipment during road construction projects. To achieve optimal leveling results, graders are equipped with automated blade control systems that respond to real-time data feedback from sensors placed on the machinery.

These systems allow graders to maintain consistent grades while minimizing human error. Pavers also undergo customizations such as automatic screed control mechanisms that ensure uniform asphalt thickness across the road surface.

Construction Equipment Modifications for Demolition Projects

Subtitle: Reinforcing Machinery for Controlled Destruction Demolition projects require construction equipment with enhanced strength and specialized attachments.

Excavators are commonly modified for these projects by reinforcing their booms and arms to withstand the tremendous forces exerted during demolition activities. This reinforcement ensures stability and safety throughout the process.

In addition to strengthening the machinery, specific attachments are added to excavators to facilitate efficient demolition. Attachments like shears are utilized to cut through steel structures, while crushers break down concrete into manageable sizes for easy removal.

These modifications allow for controlled demolition, minimizing collateral damage and ensuring worker safety. By tailoring construction equipment modifications to the unique requirements of mining, road construction, and demolition industries, project efficiency is greatly enhanced.

These specialized modifications provide equipment with increased resilience, precision engineering capabilities, and optimized functionality in specific project environments. Such customizations ultimately contribute to safer operations while delivering impressive results within these diverse sectors of the construction industry.

Niche Subtopics in Construction Equipment Modification

Rarely Known Small Details about Customization Techniques

When it comes to construction equipment modification, some lesser-known details can make a significant difference in maximizing performance and safety. Two such examples are flame-resistant coatings and noise reduction measures.

Flame-resistant coatings, often applied to the exterior of construction equipment, provide an extra layer of protection against fire hazards commonly found on construction sites. These specialized coatings are designed to withstand high temperatures and prevent the spread of flames, offering peace of mind for both operators and project managers.

Noise reduction measures may not be immediately associated with equipment customization, but they play a vital role in creating a more conducive work environment. Construction sites can be notoriously noisy due to the operation of heavy machinery.

Implementing noise reduction techniques such as sound-dampening insulation materials or mufflers can significantly reduce noise pollution levels. This not only improves the well-being of workers but also minimizes disturbance to nearby communities, leading to better community relations during construction projects.

Examples: Flame-Resistant Coatings

One particular example that showcases the significance of flame-resistant coatings is their application on excavators used for mining operations. Mining sites often involve working with volatile materials and conditions that increase the risk of fire hazards.

By applying flame-resistant coatings on excavator components prone to heat exposure such as engine compartments and hydraulic lines, the likelihood of fires spreading or igniting is greatly reduced. This protective measure ensures continued operations while prioritizing safety within these high-risk environments.

Another example where flame-resistant coatings prove beneficial is in road construction projects involving asphalt plants. Asphalt production involves heating bitumen at high temperatures which poses fire risks if not properly contained or managed.

By applying flame-resistant coatings on areas vulnerable to heat exposure, such as conveyors or storage tanks near hot mix plants, accidents resulting from ignition sources can be effectively minimized. This demonstrates how seemingly small customization details like flame-resistant coatings can have a significant positive impact on construction site safety.

How These Details Enhance Construction Equipment Modification

The integration of rarely known customization techniques, such as flame-resistant coatings and noise reduction measures, enhances the overall effectiveness of construction equipment modification. By considering these details, construction companies can provide a safer working environment for their operators and improve their

relationship with local communities by minimizing noise pollution. Additionally, customization techniques like flame-resistant coatings can safeguard expensive machinery from potential damage caused by fire incidents, ensuring that projects continue smoothly without unnecessary disruptions.

Conclusion

Exploring the niche subtopics of construction equipment modification reveals the importance of rarely known small details such as flame-resistant coatings and noise reduction measures. These customization techniques not only enhance operational performance but also prioritize safety and well-being in construction projects.

By implementing these modifications, construction companies demonstrate their commitment to promoting a positive work environment while simultaneously mitigating potential risks associated with fire hazards or excessive noise levels. The incorporation of such details showcases an optimistic outlook toward continuous improvement in the construction industry, ensuring that projects are executed efficiently and conscientiously.