Crushing and screening equipment are the workhorses of industries like mining, construction, and recycling. They are the formidable machines responsible for breaking down and sifting through diverse materials, shaping the modern world as we know it. However, what truly makes these machines versatile and indispensable is their ability to come in a wide array of sizes and capacities, tailored to specific tasks and operational scales.

Understanding the range of sizes and capacities is essential for businesses and professionals seeking the right equipment to meet their unique needs. From compact crushers suited for smaller-scale applications to heavy-duty giants capable of handling the most demanding mining projects, this article embarks on a journey to explore the diverse landscape of crushing and screening equipment. By the end, you will have a clearer perspective on how these machines can be customized and adapted to tackle an assortment of tasks, contributing to the efficiency and productivity of countless industrial operations.

1. Crushers

Crushers are the workhorses of material processing, coming in a variety of sizes to cater to an extensive range of applications. At one end of the spectrum are compact crushers, purpose-built for small-scale operations. These compact units are often mobile and nimble, making them ideal for construction and recycling projects that require flexibility and versatility. Their modest size doesn’t compromise their effectiveness, as they efficiently break down materials to meet project requirements.

On the other end of the spectrum, we find large and heavy-duty crushers, tailor-made for massive quarry and mining projects. These colossal machines can be jaw crushers, which are robust and versatile, or massive gyratory crushers with jaw-dropping throughput capacities. They are capable of processing immense quantities of material, ensuring the efficient extraction of valuable minerals in the mining industry.

This wide range of crusher sizes ensures that industries of all scales can find the right equipment to meet their specific needs, whether it’s a small-scale construction project or a colossal mining operation.

2. Screens

In the realm of screening equipment, versatility and adaptability reign supreme. This category includes a diverse array of machines, most notably vibrating screens, and scalpers, designed to meet the distinct requirements of a wide spectrum of materials and production rates.

Scalpers, the smaller counterparts in the screening family, serve as the initial gatekeepers. Typically more compact, they are engineered for the preliminary screening of coarse materials. Their primary role is to remove oversized particles, ensuring that only appropriately sized materials continue down the processing line. This initial step is crucial in preventing overloading and damage to downstream equipment.

On the other hand, larger vibrating screens excel in handling finer grading. These robust machines efficiently classify materials, separating them into different-size fractions with precision. This is particularly valuable in applications like mining and aggregate processing, where product quality and consistency are paramount.

The diverse range of screening equipment, like crushers, ensures that industries can select the perfect tool for the task, whether it involves the initial sorting of raw materials or the fine grading of processed products.

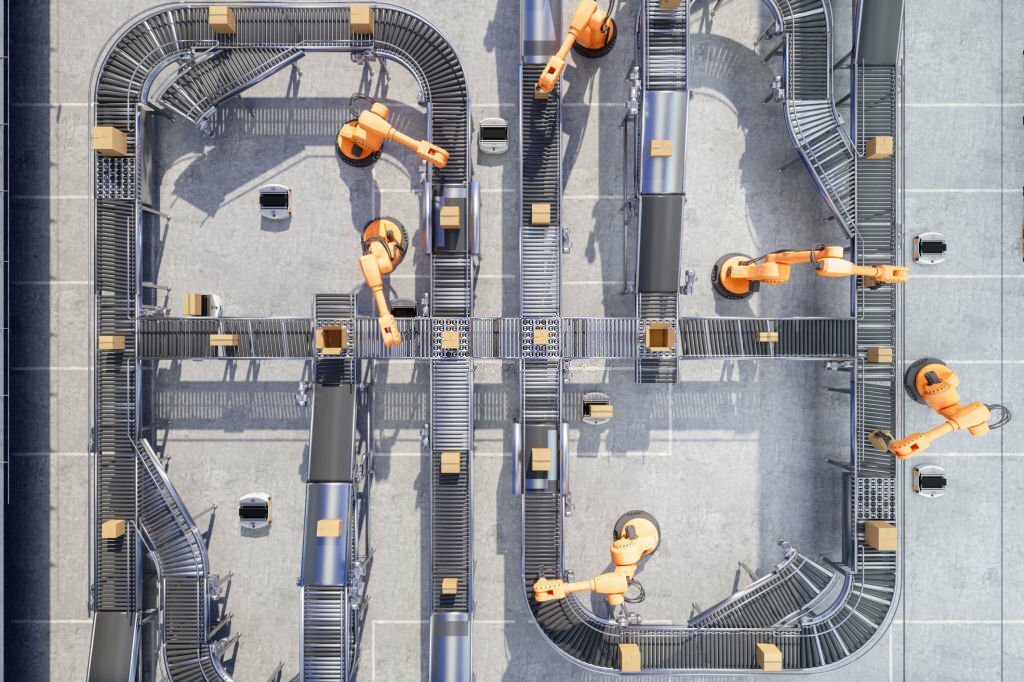

3. Conveyors

In the world of material processing, conveyor systems play a vital role as the unsung heroes behind the scenes. These often-overlooked components are the lifeblood of many industrial operations, ensuring the smooth and efficient movement of materials throughout the various stages of processing.

Conveyor systems come in a diverse range of sizes and capacities, and their configurations are highly adaptable to cater to the unique material handling requirements of different operations. Small-scale applications may utilize compact and portable conveyors, ideal for managing modest material volumes within confined spaces. On the other hand, massive mining and construction projects call for robust conveyor systems with impressive carrying capacities, capable of transporting heavy loads over long distances.

The choice of conveyor size and capacity is pivotal, as it directly impacts the overall efficiency and productivity of a processing operation. In essence, conveyor systems serve as the arteries of an industrial workflow, ensuring that crushed and screened materials seamlessly progress from one processing stage to the next. By matching the right conveyor system to specific material handling needs, businesses can optimize their operations and streamline their production processes.

4. Mobile vs. Stationary

Crushing and screening equipment comes in two primary configurations: mobile and stationary, each with its own distinct advantages and ideal use cases.

Mobile equipment is prized for its versatility and adaptability. It’s the go-to choice for operations that require flexibility and the ability to move the equipment to different work sites. Mobile crushers and screens can be transported easily, making them perfect for construction and recycling projects that involve multiple locations. They offer the convenience of on-site processing, reducing transportation costs and time.

On the other hand, stationary equipment is known for its larger size and impressive capacity. These machines are typically immobile, set up at a fixed location, and intended for high-capacity, continuous operations. They are the workhorses of mining, quarrying, and large-scale aggregate production, where the emphasis is on maximum efficiency and consistent, high-volume material processing.

The choice between mobile and stationary equipment depends on the specific needs of the operation, with mobility and versatility favored for dynamic projects, while stationary equipment excels in applications demanding uninterrupted, high-capacity processing.

5. Scalability

One of the remarkable features of crushing and screening equipment is its adaptability and customization options. Manufacturers design these machines with a focus on flexibility, allowing them to be tailored to the specific production requirements of diverse applications.

Customization and scaling are vital aspects of the equipment’s versatility. It means that these machines can be modified and configured to handle varying material types, sizes, and quantities. This adaptability is particularly valuable in industries where production demands are subject to fluctuations or where a wide range of materials must be processed.

For example, crushing equipment can be equipped with different types of crushing chambers, from standard to fine, enabling the processing of various materials with precision. Screening equipment can be fitted with different screen media, hole sizes, and deck configurations to suit the desired product specifications.

This ability to customize and scale equipment grants industries the power to efficiently adapt to changing project needs, ensuring maximum productivity and cost-effectiveness. Whether it’s adjusting to new material sources, adapting to different grading requirements, or optimizing production for shifting demands, the versatility of crushing and screening equipment proves to be a valuable asset in various industrial settings.

In the world of industrial material processing, the diversity of crushing and screening equipment sizes and capacities is nothing short of remarkable. This adaptability allows industries to select the perfect tools for their specific needs, be it in mining, construction, or recycling. From compact crushers designed for small-scale operations to massive, heavy-duty giants engineered for large mining endeavors, the options are extensive. Scalpers and vibrating screens range from preliminary sorting to precision grading. Conveyors, whether compact or colossal, ensure seamless material flow. The choice between mobile and stationary units adds another layer of customization. In a constantly changing industrial landscape, the ability to customize and scale equipment grants businesses the agility they need to meet their evolving project requirements efficiently and effectively.

To deepen your understanding of the diverse sizes and capacities of crushing and screening equipment, visit the Boom and Bucket website. Explore our comprehensive guide to select the perfect equipment for your industrial needs. Whether you are a professional in the industry or an enthusiast seeking insights, our resource provides valuable information to help you make informed decisions. Visit our website today and embark on a journey of discovery.