Introduction:

In the realm of heavy equipment, the efficiency and success of various industries like mining, construction, and exploration largely hinge on the utilization of advanced drilling equipment. These robust machines have revolutionized the way we dig, extract resources, and construct vital structures. From penetrating the earth’s surface to accessing underground reserves, plays an indispensable role. This article is a comprehensive exploration of the different types of drilling equipment used in heavy equipment , shedding light on their functionalities and contributions to the industries they serve.

1. Rotary Drills: Pioneers of Deep Excavations

Rotary drills are undoubtedly the stalwart backbone of the drilling equipment domain, particularly within heavy-duty contexts. Unquestionably robust, these machines function through a strategic combination of rotational force and vertical pressure, seamlessly facilitating the excavation process. Their indispensability is underscored by their widespread usage across diverse sectors, including mining, oil exploration, and large-scale construction initiatives, where their remarkable efficiency and precision are keenly relied upon.

An intrinsic feature of rotary drills is their versatility, manifested through an assortment of sizes and configurations tailored to the unique demands of each operation. This adaptability ensures that the machinery can effectively accommodate varying project requirements, thereby enhancing its applicability across a spectrum of industries. Notably, their adeptness in penetrating even the most formidable rock formations, coupled with their capacity to extract coveted resources from deep within the Earth, cements their pivotal role in complex and arduous excavation ventures.

In essence, the formidable stature of rotary drills lies not only in their mechanical prowess but also in their profound impact on the seamless execution of intricate drilling tasks. As fundamental components of the modern industrial landscape, these drills continue to uphold their reputation as indispensable tools for driving monumental feats of engineering and resource extraction.

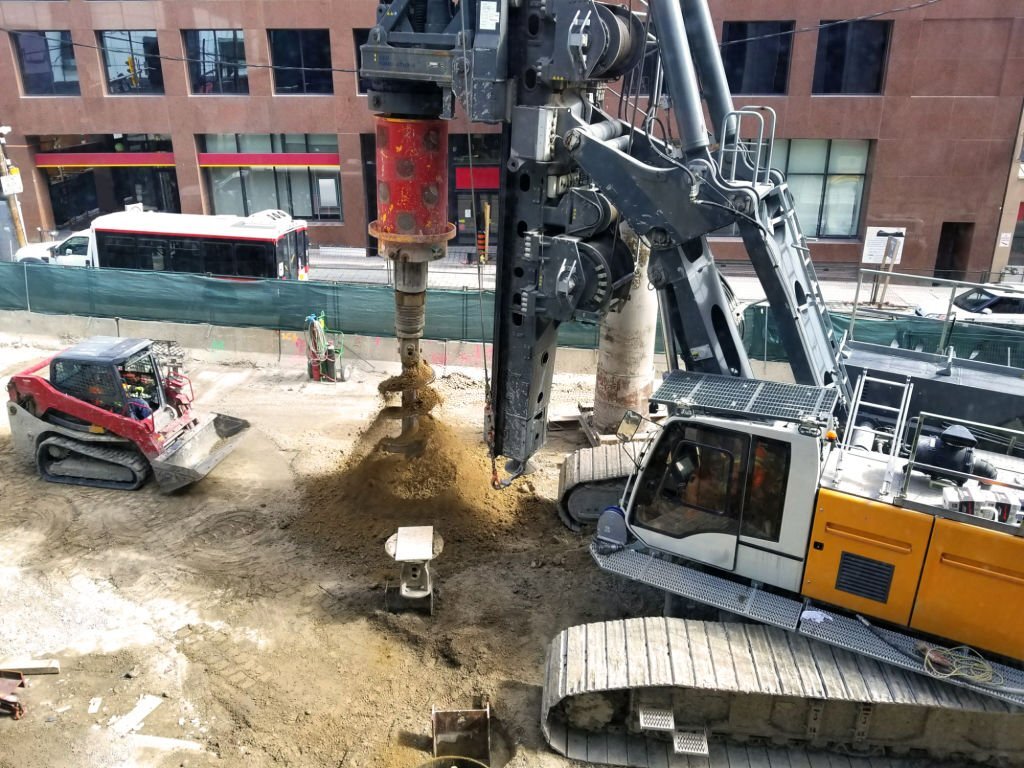

2. Augers: Unearthing Efficiency

Augers represent a versatile class of drilling apparatus, recognized for their paramount role in facilitating the excavation of soil and sedimentary materials. Comprising a pivotal helical screw blade, known as the flight, affixed to a rotating shaft, these tools epitomize ingenuity in simplifying drilling processes. Their predominant application within the construction sector revolves around the seamless creation of cavities for essential infrastructure elements such as building foundations and fence posts. Moreover, their utility extends to the agricultural realm, where they prove instrumental in expediting the planting of crops and other cultivation tasks.

Augers notably excel in accommodating softer ground compositions, leveraging their intrinsic design to swiftly and accurately carve holes of varying diameters. This unparalleled efficiency, coupled with their remarkable precision, solidifies their position as indispensable assets in both construction and agricultural landscapes, facilitating the execution of vital tasks with unparalleled ease and efficacy.

3. Core Drills: Extracting Geological Insights

The profound significance of core drilling equipment lies in its distinctive capability to procure cylindrical specimens, commonly known as cores, from the intricate layers of rock and soil. These invaluable samples serve as pivotal windows into the underlying geological intricacies and formations that shape the Earth’s subsurface, unraveling a wealth of information crucial for diverse scientific and industrial pursuits. Operating as the linchpin of numerous mining and exploration endeavors, core drills play a pivotal role in unraveling the mysteries of the Earth’s crust, enabling geologists and researchers to discern the presence of valuable minerals, evaluate the feasibility of extraction endeavors, and comprehensively examine the geological dynamics at play.

Essentially serving as the bedrock for well-informed decision-making, core drilling emerges as an indispensable tool in the assessment of the practical viability and potential yield of resource extraction initiatives. By meticulously extracting and analyzing core samples, mining, and exploration experts can gain invaluable insights into the geophysical properties, structural characteristics, and overall potential of subsurface resources, thereby laying the groundwork for strategic planning and resource management in an array of industrial sectors. As a result, core drilling equipment stands as an instrumental linchpin in the ongoing pursuit of unraveling the Earth’s geological mysteries and harnessing its bountiful resources with precision and foresight.

4. Directional Drills: Navigating Subsurface Challenges

Directional drilling has undeniably sparked a paradigm shift in the realm of subterranean construction, particularly in the seamless establishment of crucial underground structures, such as pipelines and utility conduits. Diverging from conventional drilling practices that adhere to a vertical trajectory, directional drills wield the transformative ability to alter their angle and orientation, thereby enabling meticulous maneuvering through intricate and challenging subsurface landscapes. This unprecedented flexibility in trajectory empowers engineers and construction professionals to meticulously navigate around a myriad of obstacles, ranging from existing infrastructural frameworks to geological complexities, ensuring the precise and unobtrusive installation of vital subterranean networks.

The unparalleled versatility of directional drilling manifests as a critical asset, especially within bustling urban settings, where the terrain is often densely populated with preexisting structures and intricate utility systems. By circumventing the need for extensive surface excavation, this cutting-edge equipment mitigates the risk of disruptive surface disturbances, minimizing the potential for disruptive urban sprawl, and significantly reducing the overall environmental footprint of construction endeavors. Consequently, directional drilling has emerged as the preferred modus operandi for urban construction projects, accentuating its role as a cornerstone of contemporary infrastructure development, fostering efficient, sustainable, and minimally invasive approaches to subterranean construction within the dynamic and ever-evolving urban landscape.

5. Hammer Drills: Powering Through Tough Surfaces

Hammer drills, renowned for their alias as percussion drills, epitomize a fusion of rotary motion and pulsating hammering action, a distinctive amalgamation that endows them with the exceptional capability to seamlessly penetrate formidable materials, including concrete, masonry, and rock. Their resolute presence within the construction and renovation sphere is primarily attributed to their proficiency in meticulously crafting holes for pivotal components such as anchor bolts, fasteners, and electrical installations, effectively serving as the vanguards of precision and efficacy in modern construction practices. Significantly, their remarkable prowess lies in their ability to create cavities within robust surfaces without causing disproportionate damage, ensuring that the structural integrity of the materials remains intact. Through their unparalleled dexterity and finesse, hammer drills have solidified their reputation as indispensable tools, facilitating the seamless execution of intricate construction tasks while upholding the paramount principles of precision, durability, and structural integrity within the realm of contemporary construction practices.

6. Hydraulic Drills: Force and Precision Combined

Hydraulic drills stand as towering pillars of strength and precision within the expansive domain of drilling, harnessing the unparalleled prowess of hydraulic pressure to propel their intricate drilling mechanisms. The seamless integration of robust hydraulic power and intricate engineering endows these formidable machines with an extraordinary amalgamation of sheer force and unparalleled accuracy, establishing them as the quintessential tools of choice for the most arduous and demanding heavy-duty assignments. Their resolute presence within the industrial landscape finds its most profound resonance within the realms of mining, quarrying, and tunneling, where their unwavering might and precision craftsmanship orchestrate a symphony of efficiency and productivity. As instrumental contributors to the unyielding pursuit of mineral extraction and subterranean exploration, hydraulic drills have garnered a resounding ovation within these critical sectors, elevating the standards of efficiency, reliability, and performance within the intricate tapestry of contemporary industrial operations.

7. Pressure Drills: Deep-Sea Exploration

Pressure drilling equipment assumes a pivotal and specialized role within the complex fabric of drilling technology, embarking on a daring journey into the unfathomable depths of the ocean with a precise mission – to unlock the boundless wealth harbored within the elusive offshore oil reserves. Operating as an indispensable tool in the realm of underwater drilling, this specialized category of drilling apparatus assumes paramount importance, particularly within the expansive domain of offshore exploration, where the ocean’s enigmatic vastness veils its abundant riches beneath layers of tempestuous waters. With its sophisticated design and robust engineering, pressure drilling equipment serves as a beacon of technological ingenuity, navigating the formidable challenges posed by the oceanic environment to extract the invaluable resources concealed beneath the ocean floor. As a vanguard of modern offshore drilling expeditions, this equipment epitomizes the relentless pursuit of harnessing the untapped potential of the deep sea, propelling the trajectory of global energy exploration and resource acquisition towards unprecedented frontiers of innovation and sustainability.

8. Drilling rigs

Celebrated as the unsung champions of modern-day exploration, drilling rigs emerge as towering testaments to the unparalleled feats of engineering ingenuity. These colossal structures, meticulously tailored to conquer the unfathomable depths, serve as steadfast sentinels unraveling the enigmatic mysteries veiled beneath the Earth’s surface. From the sprawling domain of oil and gas to the intricate realms of mining and geothermal energy, drilling rigs assume the role of indomitable pioneers, reshaping the boundaries of what is deemed achievable within the intricate tapestry of resource extraction and scientific inquiry.

At their very essence, drilling rigs embody a harmonious fusion of mechanical finesse and cutting-edge technological sophistication. Their towering derricks and intricately woven machinery choreograph an intricate symphony, propelling the drill bits with unwavering determination into the profound depths of the Earth, giving birth to profound boreholes that serve as gateways to both invaluable resources and profound insights into the Earth’s geological composition. Whether delving into the depths of underground oil reservoirs or delving into the mysteries of the planet’s intricate composition, these monumental drilling rigs stand as the conduits of discovery, ushering humanity into an era of unparalleled exploration, innovation, and scientific enlightenment.

Geothermal Drilling: Tapping Earth’s Hidden Energy Reserves

In the realm of sustainable energy solutions, geothermal drilling emerges as a silent yet potent contender, harnessing the Earth’s internal heat to power communities and industries. This innovative approach to energy generation offers a renewable source of power with minimal environmental impact. Geothermal drilling, a captivating synergy of technology and natural forces, stands as a beacon of sustainable progress.

At its core, geothermal drilling seeks to unlock the Earth’s immense reservoirs of heat stored beneath its surface. This heat, generated by the natural processes of radioactive decay and residual planetary formation, can be tapped into through specialized drilling techniques. Geothermal energy, harnessed by capturing the steam or hot water that rises from these underground reservoirs, offers a consistent and dependable power source.

The drilling industry propels progress, carving pathways through Earth’s layers for resources, knowledge, and innovation. From extracting fuels to shaping foundations, drilling is the heartbeat of construction, energy, and exploration, forging the foundations of modern life with every borehole and well sunk into the Earth’s embrace.

In the dynamic realm of the construction and drilling industries, the indispensable role of drilling equipment and various construction equipment operators underscores the pivotal significance of proper operating procedures and safety practices. From towering construction sites to sprawling drilling rigs, the synergy between safety equipment and operating engineers orchestrates a secure work environment. As hands adroitly handle hand and power tools, the responsibility to operate and maintain equipment rests heavily on the shoulders of skilled professionals adept in geothermal drilling and other specialized domains. Meticulously following operating procedures and conducting routine maintenance, these professionals, often with a high school diploma as a baseline, may undergo intensive training programs or apprenticeships to fortify their expertise. Within the rhythmic symphony of the construction industry, the harmonious coordination of heavy equipment operators, motor graders, and other crew members invigorates the heartbeat of ambitious construction projects. With an unwavering commitment to safety and proficiency, the amalgamation of power tools, equipment, and human expertise propels the drilling industry and the construction sector towards unprecedented milestones.

Conclusion:

In the dynamic world of heavy equipment, drilling takes center stage, driving progress across industries like mining, construction, and exploration. From rotary drills for deep excavations to directional drills for navigating complex environments, each type of drilling equipment brings its unique capabilities to the table. Augers, core drills, hammer drills, hydraulic drills, and pressure drills further enrich the toolkit, showcasing the versatility and innovation present in modern heavy equipment. As technology continues to advance, these drilling types will undoubtedly evolve, shaping the future of heavy-duty on a global scale.

Центр реабилитации – путь к лучшему здоровью

реабилитация больных [url=медицинская-реабилитация.москва]медицинская-реабилитация.москва[/url].